Advanced Additive Manufacturing and Topology Optimization

MECH 6910S

Course Description

This course introduces seven state-of-the-art additive manufacturing (AM)

technologies that apply to

various materials. The physical principle, theoretical modeling, and the effects

of different process

parameters are derived and analyzed. Based on the knowledge of the AM processes,

computer-aided

tools, and specific design principles for AM are also discussed.

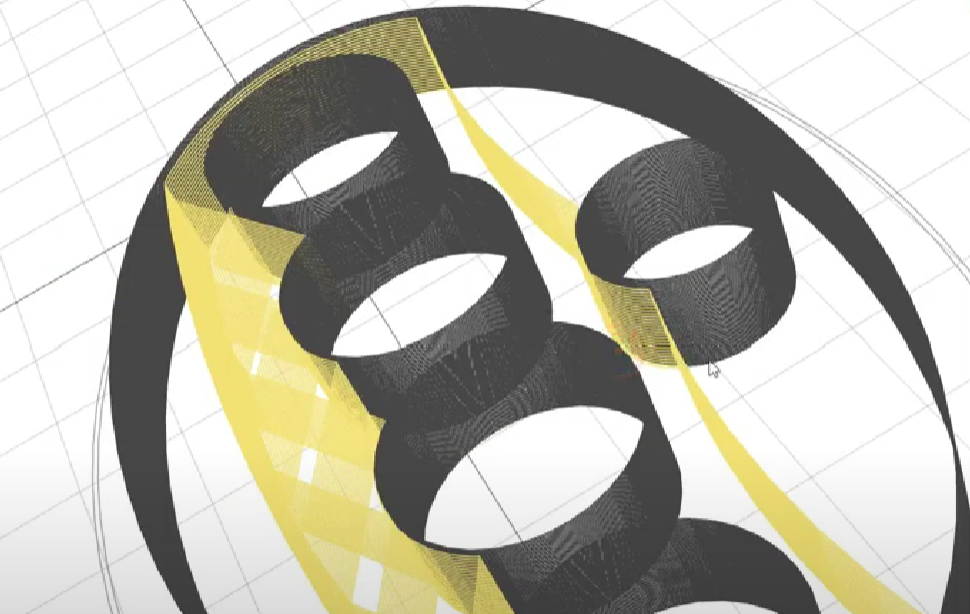

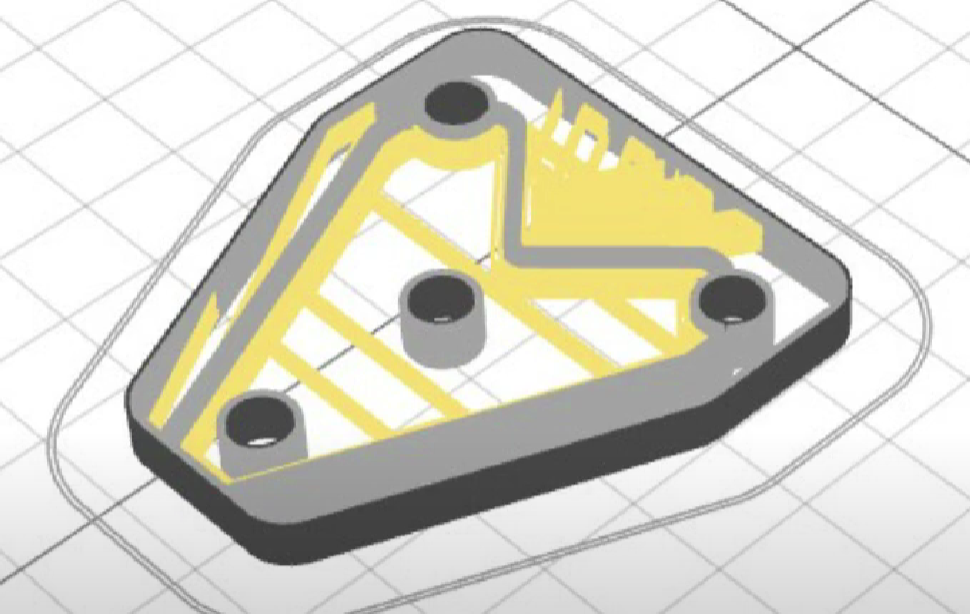

Among the design guidelines, the concept and practices of topology optimization

are highlighted. The

students will learn to generate structurally optimal designs based on loads,

constraints, and other

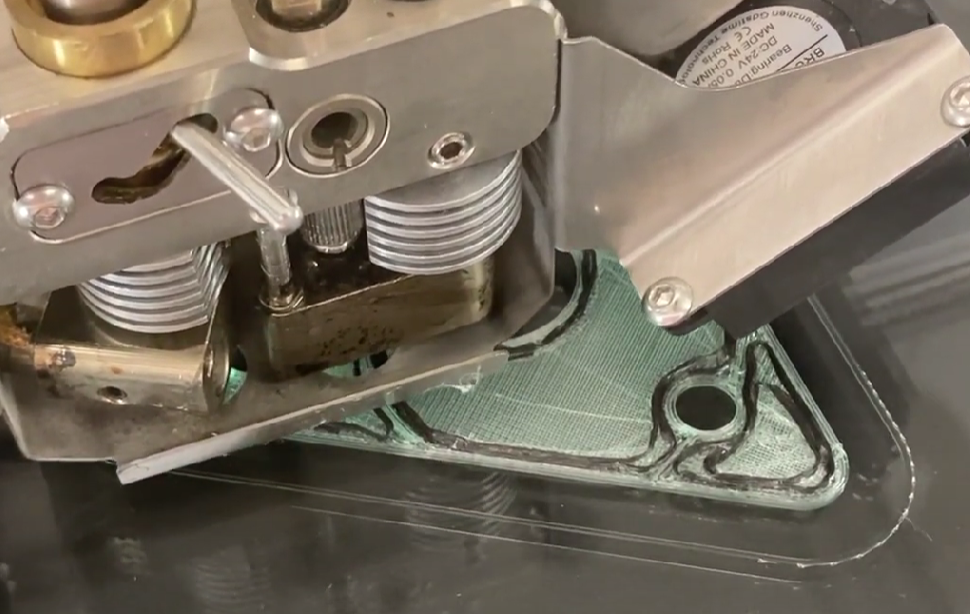

required product performance and manufacturing conditions. The course also

provides experimental

sessions to manufacture the structural optimized parts with either metal

selective laser sintering or

continuous fiber-reinforced additive manufacturing.